1) Enwere ike kewaa ya n'ụdị ndị a site na iji:

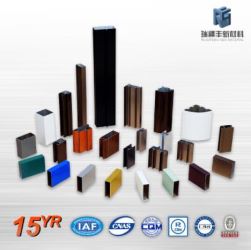

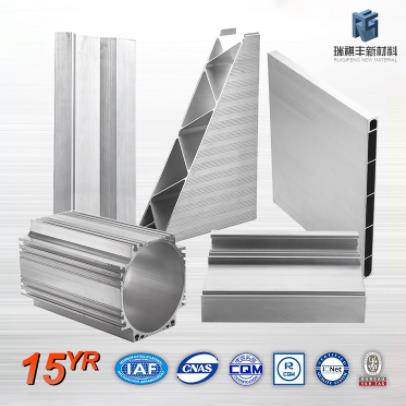

1. Ụlọ profaịlụ aluminum (gụnyere ọnụ ụzọ, windo na mgbidi ákwà mgbochi)

2. Aluminom profaịlụ nke radiator.

3. General ulo oru aluminum profaịlụ: ha na-tumadi ji maka ulo oru mmepụta na n'ichepụta, dị ka akpaka n'ibu akụrụngwa, mkpuchi kpuchie, na ahaziri ebu oghere site ụlọ ọrụ dị ka ha onwe ha n'ibu ngwá chọrọ, dị ka mgbakọ akara ebu eriri, mbuli, igwe na-ekesa, ule ngwá, shelf, wdg ọtụtụ n'ime ha na-eji na electronic igwe ụlọ ọrụ na uzuzu-free ụlọ.

4. Aluminom alloy profaịlụ maka ụgbọ okporo ígwè Ọdịdị: tumadi eji maka n'ichepụta ụgbọ okporo ígwè ahụ.

5. Ugwu Aluminom profaịlụ, na-eme ka aluminum alloy picture okpokolo agba, na ugwu dị iche iche ngosi na e ji achọ eserese.

2) Nhazi site na ngwakọta alloy

Enwere ike kewaa ya na 1024, 2011, 6063, 6061, 6082, 7075 na ọkwa alloy ndị ọzọ nke profaịlụ aluminum, nke usoro 6 kachasị. Ihe dị iche n'etiti ụdị dị iche iche na-adabere na nha dị iche iche nke ihe dị iche iche metal. Ewezuga profaịlụ aluminom nke a na-ejikarị eme ihe maka ọnụ ụzọ na windo, dị ka usoro 60, usoro 70, usoro 80, usoro 90, usoro mgbidi ákwà mgbochi na profaịlụ aluminom ndị ọzọ na-arụ ọrụ, enweghị ihe ngosi doro anya maka profaịlụ aluminom ụlọ ọrụ. Ọtụtụ ndị na-emepụta ihe na-ahazi ha dịka eserese ndị ahịa si dị

3) Ụdị ojiji nke ọkwa dị iche iche nke aluminum alloys

1050: coils extruded maka nri, kemịkalụ na ụlọ ọrụ mmepụta ihe, hoses dị iche iche, ntụ ọkụ ọkụ.

1060: oge chọrọ nguzogide corrosion dị elu na nhazi, mana ọ bụghị ike dị elu. Ngwa kemịkalụ bụ ihe eji eme ya

1100: eji maka nhazi akụkụ na components na-achọ ezi formability na elu corrosion eguzogide ma ọ dịghị achọ elu ike, dị ka chemical ngwaahịa, nri ụlọ ọrụ ngwaọrụ na nchekwa containers, mpempe akwụkwọ nhazi akụkụ, miri ịbịaru ma ọ bụ spinning concave arịa, ịgbado ọkụ akụkụ na components, okpomọkụ Exchangers, e biri ebi mbadamba, aha plates, na-egosipụta ngwa ngwa.

1145: nkwakọ ngwaahịa na mkpuchi aluminum foil, okpomọkụ Exchanger

1199: electrolytic capacitor foil, ihe nkiri na-egosipụta ngosipụta anya

Profaịlụ aluminom (Ibé akwụkwọ 6)

1350: waya, conductive strands wire, busbar, transformer strip

2011: kposara na ngwaahịa igwe na-arụ ọrụ nke ọma

2014: eji mee ihe n'oge chọrọ ike dị elu na ike (gụnyere okpomọkụ dị elu). Ụgbọ elu dị arọ, forgings, nnukwu efere na ihe extruded, wiil na structural ọcha, akpa ogbo mmanụ ụgbọala tank nke multi-stage rọketi na ugbo elu akụkụ, gwongworo etiti na nkwusioru usoro akụkụ.

2017: ọ bụ alloy usoro 2XXX mbụ iji nweta ngwa ụlọ ọrụ. Ka ọ dị ugbu a, oke ngwa ya dị warara, ọkachasị gụnyere rivets, akụkụ igwe n'ozuzu ya, akụkụ nhazi nke ihe owuwu na ngwa njem, propeller na ngwa.

2024: ihe owuwu ụgbọ elu, rivets, akụrụngwa ogbunigwe, ọdụ ụgbọ ala, akụrụngwa propeller na ihe ndị ọzọ arụrụ arụ

2036: Akụkụ ahụ mpempe akwụkwọ akpaaka

2048: akụkụ aerospace structural akụkụ na ngwá agha structural akụkụ

2124: Ọdịdị ikuku

2218: injin ụgbọ elu na piston injin diesel, isi igwe cylinder ụgbọ elu, ihe na-ebugharị ụgbọ elu na mgbanaka compressor

2219: oghere rọketi ịgbado ọkụ oxidizer tank, supersonic ụgbọ elu akpụkpọ na bughi akụkụ, arụ ọrụ okpomọkụ bụ -270 ~ 300 ℃. Ọdịmma weld dị mma, ike mgbaji dị elu, yana oke nrụgide corrosion mgbawa na steeti T8

2319: electrode na filler metal maka ịgbado ọkụ na ịbịaru 2219 alloy

2618: anwụ forgings na free forgings. Piston na Aeroengine Akụkụ

2a01: rivets arụ ọrụ na-arụ ọrụ na-erughị ma ọ bụ hà nhata 100 ℃

2A02: axial compressor agụba nke turbojet engine na arụ ọrụ okpomọkụ nke 200 ~ 300 ℃

2A06: ụgbọ elu Ọdịdị na-arụ ọrụ okpomọkụ nke 150 ~ 250 ℃ na ụgbọ elu Ọdịdị rivet na-arụ ọrụ okpomọkụ nke 125 ~ 250 ℃

2a10: ike dị elu karịa nke 2a01 alloy. A na-eji ya arụpụta rivets nhazi ụgbọ elu na-arụ ọrụ okpomọkụ na-erughị ma ọ bụ hà nhata 100 ℃

2A11: ndị otu nhazi ike ọkara, agụba propeller, ngwa njem na ndị otu ụgbọ elu na-ewu ụlọ. Ọkara ike bolts na rivets maka ụgbọ elu 2A12 akpụkpọ anụ, spacer frame, nku ọgịrịga, nku doo, rivet, wdg, na bughi akụkụ nke ụlọ na njem ụgbọ ala.

2A14: free forgings na anwụ forgings nwere mgbagwoju shapes

2A16: aerospace ụgbọ elu akụkụ na-arụ ọrụ okpomọkụ nke 250 ~ 300 ℃, welded arịa na airtight kokpiiti na-arụ ọrụ na ụlọ okpomọkụ na elu okpomọkụ.

2a17: ụgbọ elu akụkụ na-arụ ọrụ okpomọkụ nke 225 ~ 250 ℃

2A50: akụkụ ike ọkara nwere ọdịdị dị mgbagwoju anya

2a60: ugbo elu engine compressor wheel, ikuku ndu wheel, onye ofufe, impeller, wdg

2A70: akpụkpọ ụgbọ elu, piston ụgbọ elu, wheel ndu ikuku, diski wheel, wdg

2A80: aeroengine compressor agụba, impellers, pistons, mgbanaka mgbasa na akụkụ ndị ọzọ nwere oke ọrụ okpomọkụ.

2a90: piston aeroengine

3003: ọ na-eji hazie akụkụ na components na ezi formability, elu corrosion eguzogide na weldability, ma ọ bụ na-arụ ọrụ na-achọ ma ndị a Njirimara na elu ike karịa 1xxx usoro alloy, dị ka kichin arịa, nri na chemical ngwaahịa nhazi na nchekwa ngwaọrụ, tankị na tankị maka ibufe mmiri mmiri ngwaahịa, na dị iche iche nrụgide arịa na pipelines esichara na mkpa efere.

3004: All aluminom Mkpọ na-chọrọ ka nwere akụkụ na elu ike karịa 3003 alloy, chemical ngwaahịa mmepụta na nchekwa ngwaọrụ, mpempe akwụkwọ nhazi akụkụ, ụlọ nhazi akụkụ, ụlọ ngwá ọrụ, na dị iche iche oriọna akụkụ.

3105: nkebi ụlọ, baffle, ibugharị ụlọ efere, gutter na downpipe, mpempe akwụkwọ metal akpụ akụkụ, karama okpu, corks, wdg

3A21: tank mmanụ ụgbọ elu, eriri mmanụ, waya rivet, wdg; Ihe owuwu ụlọ, nri na akụrụngwa mmepụta ihe ndị ọzọ

5005: yiri 3003 alloy, ọ nwere ike ọkara na ezigbo nguzogide corrosion. A na-eji ya dị ka onye nduzi, osi ite, ogwe ngwá ọrụ, shei na ihe ịchọ mma ụlọ. Ihe nkiri anodic oxide na-egbuke egbuke karịa ihe nkiri oxide na 3003 alloy na kwekọrọ na hue nke 6063 Alloy.

5050: Enwere ike iji efere ahụ dị gịrịgịrị dị ka efere mkpuchi nke refrjiraeto na refrjiraeto, ọkpọkọ gas ụgbọ ala, ọkpọkọ mmanụ na ọkpọkọ mmiri ugbo; Ọ nwekwara ike hazie nnukwu efere, ọkpọkọ, mmanya, ihe profaịlụ na mkpanaka waya, wdg

5052: Alloy a nwere ezigbo nhazi, nguzogide corrosion, mgbochi oriọna, ike ike ọgwụgwụ na ike static. A na-eji ya arụpụta tank mmanụ ụgbọ elu, ọkpọkọ mmanụ, akụkụ mpempe akwụkwọ nke ụgbọ okporo ígwè na ụgbọ mmiri, ngwá ọrụ, oriọna na-akwado na rivets, ngwaahịa ngwaike, wdg.

5056: magnesium alloy na cable sheath rivet, zipa, ntu, wdg; A na-eji wires mkpuchi aluminom eme ihe n'ọtụtụ ebe maka nhazi mkpuchi mkpuchi ụmụ ahụhụ na oge ndị ọzọ na-achọ nnukwu nguzogide corrosion.

5083: eji mee ihe maka oge chọrọ nguzogide corrosion dị elu, ezigbo weldability na ike ọkara, dị ka ụgbọ mmiri, ụgbọ ala na welded efere ụgbọ elu; Ụgbọ mmiri nrụgide, ngwaọrụ jụrụ oyi, ụlọ elu TV, akụrụngwa na-egwupụta ihe, akụrụngwa njem, ngwa agha, ngwa agha, wdg ndị chọrọ mgbochi ọkụ siri ike.

5086: eji mee ihe maka oge chọrọ nguzogide corrosion dị elu, ezigbo weldability na ike ọkara, dị ka ụgbọ mmiri ụgbọ mmiri, ụgbọ ala, ụgbọ elu, akụrụngwa cryogenic, ụlọ elu telivishọn, mpaghara mkpọ ala, akụrụngwa ụgbọ njem, akụkụ ngwa agha na decks, wdg.

5154: Ihe owuwu welded, tankị nchekwa, ụgbọ mmiri nrụgide, ihe owuwu ụgbọ mmiri na nrụnye nke oke osimiri, tankị njem.

5182: A na-eji efere dị mkpa iji hazie mkpọ, akụkụ ahụ akpaaka, ogwe njikwa, stiffeners, brackets na akụkụ ndị ọzọ.

5252: eji maka imepụta akụkụ ịchọ mma nwere ike dị elu, dị ka akụkụ ihe eji achọ mma nke ụgbọ ala. Ihe nkiri oxide na-egbuke egbuke na nke na-egbuke egbuke mgbe oxidation anodic gasịrị

5254: mkpanaka aluminom magnesium alloy ịgbado ọkụ na wires nwere magnesium ọdịnaya karịa 3% maka hydrogen peroxide na ngwaahịa ngwaahịa ndị ọzọ.

5454: ihe owuwu welded, arịa nrụgide, pipeline nke ihe owuwu dịpụrụ adịpụ

5456: efere ihe agha, ihe siri ike welded, tankị nchekwa, ụgbọ nrụgide, ihe ụgbọ mmiri

5457: akụkụ eji achọ mma nke ụgbọ ala na akụrụngwa ndị ọzọ mgbe polishing na anodizing

5652: igbe nchekwa maka hydrogen peroxide na ngwaahịa kemịkalụ ndị ọzọ

5657: akpaaka na akụrụngwa ndị ọzọ ji achọ akụkụ nke e polished na anodized, ma n'ọnọdụ ọ bụla ga-hụ na ihe onwunwe nwere ezi ọka Ọdịdị 5A02 ụgbọ elu mmanụ ụgbọala tank na conduit, ịgbado ọkụ waya, rivet, ụgbọ mmiri structural akụkụ.

5A03: usoro ịgbado ọkụ ọkara, akụkụ stamping oyi, arịa ịgbado ọkụ, wired ịgbado ọkụ, nke enwere ike iji dochie alloy 5A02

5A05: ndị otu nhazi welded, ọkpụkpụ akpụkpọ ụgbọ elu

5A06: welded Ọdịdị, oyi na-anwụ anwụ esorowo akụkụ, welded na sere akụkụ nchegbu arịa, ụgbọ elu akpụkpọ ọkpụkpụ akụkụ

5A12: welded structural members, bulletproof deck

6005: Profaịlụ extruded na ọkpọkọ, ejiri maka ịchọ ike karịa

6063: akụkụ ihe nhazi alloy, dị ka ubube, antenna TV, wdg

6009: ogwe ahụ ụgbọ ala

6010: Mpempe akwụkwọ: ahụ ụgbọ ala

6061: dị iche iche ụlọ ọrụ mmepụta ihe na-achọ ụfọdụ ike, weldability na elu corrosion nguzogide, dị ka ọkpọkọ, mkpara, shapes na efere maka imepụta gwongworo, ụlọ elu, ụgbọ mmiri, trams, ngwá ụlọ, n'ibu akụkụ, nkenke machining, wdg

6063: profaịlụ mmepụta ihe, profaịlụ ụlọ, ọkpọkọ ogbugba mmiri na ihe extruded maka ụgbọ ala, nkwụnye, ngwá ụlọ, fences, wdg.

6066: ihe extruded maka forgings na welded owuwu

6070: ihe extruded na tubes maka arụ ọrụ welded dị arọ na ụlọ ọrụ ụgbọ ala.

6101: Ogwe ike dị elu, ndị na-eduzi ọkụ eletrik na akụrụngwa ikpo ọkụ maka ụgbọ ala

6151: eji maka anwụ na-emepụta akụkụ crankshaft, akụkụ igwe na mmepụta nke mgbanaka mpịakọta, nke ọ bụghị naanị na-achọ ezigbo malleability, ike dị elu, kamakwa ezigbo nguzogide corrosion.

6201: nnukwu ike conductive mmanya na waya

6205: nnukwu efere, pedals na nnukwu mmetụta na-eguzogide extrusion

6262: akụkụ akụkụ nrụgide dị elu nke eriri na-eguzogide corrosion dị mma karịa alloy 2011 na 2017

6351: extruded structural akụkụ nke ụgbọ ala, nnyefe pipeline maka mmiri, mmanụ, wdg

6463: ụlọ na profaịlụ ngwa dị iche iche, yana akụkụ ihe ịchọ mma ụgbọ ala nwere elu na-egbuke egbuke mgbe ọgwụgwọ anodic oxidation gasịrị.

6A02: akụkụ engine ụgbọ elu, forgings na anwụ forgings nwere mgbagwoju shapes

7005: A na-eji ihe extruded emepụta ihe owuwu welded nke nwere ike dị elu yana ike mgbaji dị elu, dị ka trusses, mkpanaka na arịa ụgbọ ala; Nnukwu ndị na-ekpo ọkụ na-ekpo ọkụ na akụkụ ndị na-enweghị ike ịkwado ọgwụgwọ ngwakọta siri ike mgbe ịgbado ọkụ; Enwere ike iji ya rụọ akụrụngwa egwuregwu dịka raket tennis na bọọlụ softball

7039: igbe refrigerated, ngwa cryogenic na tankị nchekwa, akụrụngwa nrụgide ọkụ, akụrụngwa agha, efere ngwa agha, ngwa agha.

7049: A na-eji ya na-emepụta akụkụ ndị nwere otu ike static dị ka 7079-t6 alloy na-achọ nnukwu nrụgide corrosion mgbawa, dị ka ụgbọ elu na akụkụ ngwa agha - landing gear hydraulic cylinders and extrusions. Ngwongwo ike ọgwụgwụ nke akụkụ ahụ hà nhata nke alloy 7075-T6, mana ike dị ntakịrị elu.

7050: efere dị arọ na nke dị arọ, extrusions, forgings n'efu na ịnwụ forgings maka akụkụ nhazi ụgbọ elu. Ihe achọrọ maka alloy maka imepụta akụkụ ndị dị otú ahụ bụ: nnukwu iguzogide spalling corrosion, nrụgide corrosion cracking, mgbaji siri ike na ike ọgwụgwụ.

7072: ntụ oyi aluminum foil na ultra mkpa warara; Mkpuchi nke 2219, 3003, 3004, 5050, 5052, 5154, 6061, 7075, 7475, 7178 alloy efere na ọkpọkọ.

7075: eji maka imepụta ihe owuwu ụgbọ elu yana akụkụ akụkụ nke nrụgide dị elu na ebu nwere ike dị elu na nguzogide corrosion.

7175: eji maka imepụta ihe owuwu dị elu maka ụgbọ elu. T736 ihe nwere ezigbo ihe zuru oke, ntụgharị ike dị elu, nguzogide corrosion na-eguzogide, nrụgide corrosion mgbawa nguzogide, mgbaji siri ike na ike ike ọgwụgwụ.

7178: akụkụ nwere nnukwu ike mkpụrụ maka Aerospace

7475: aluminum clad and non aluminum clad plates for fuselage, wing frames, stringers, etc. Akụkụ ndị ọzọ nwere ike dị elu na ike mgbaji.

7A04: akpụkpọ ụgbọ elu, skru, na ihe ndị nwere nrụgide dị ka eriri eriri, oghere oghere, ọgịrịga nku, ihe mgbada, wdg.

Oge nzipu: Jun-07-2022