Akụkụ 2. Teknụzụ: aluminom extrusion + esemokwu na-akpali ịgbado ọkụ dị ka isi, ịgbado ọkụ laser na FDS ma ọ bụ bụrụ ntụzịaka ga-eme n'ọdịnihu.

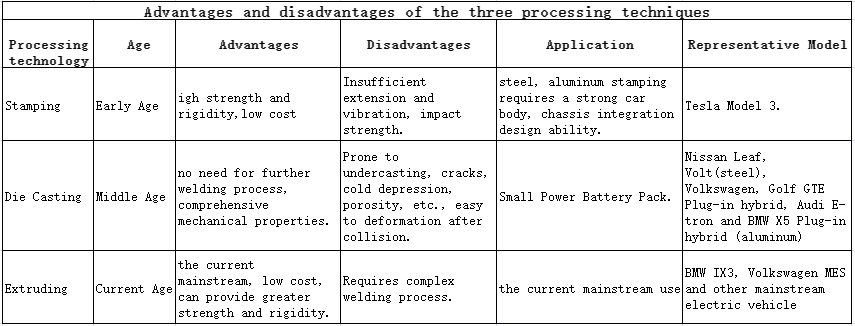

1. Tụnyere ọnwụ nkedo na stamping, aluminum extrusion kpụrụ profaịlụ na mgbe ahụ ịgbado ọkụ bụ mainstream technology nke batrị igbe ugbu a.

1) Ihe omimi nke shei n'okpuru ngwugwu batrị welded site na stamping aluminom efere, ezughị oke ịma jijiji na ike mmetụta nke batrị batrị, na nsogbu ndị ọzọ na-achọ ka ụlọ ọrụ ụgbọ ala nwee ikike imewe siri ike nke ahụ na chassis;

2) Ihe nkedo aluminom batrị tray na anwụ nkedo mode nakweere dum otu oge ịkpụzi. Ihe ọghọm dị na ya bụ na alloy aluminom na-adịkarị mfe nkedo, mgbawa, ikewapụ oyi, ịda mbà n'obi, porosity na ntụpọ ndị ọzọ na usoro nkedo. Ihe mkpuchi nke ngwaahịa mgbe nkedo adịghị mma, na elongation nke ihe nkedo aluminom alloy dị ala, nke na-adịkarị mfe nrụrụ mgbe nkwekọrịta gasịrị;

3) Extruded aluminom alloy batrị tray bụ ugbu a mainstream batrị tray imewe atụmatụ, site splicing na nhazi nke profaịlụ izute dị iche iche mkpa, nwere uru nke mgbanwe imewe, adaba nhazi, mfe gbanwee na na; Arụmọrụ Extruded aluminum alloy tray batrị nwere nnukwu rigidity, vibration iguzogide, extrusion na mmetụta arụmọrụ.

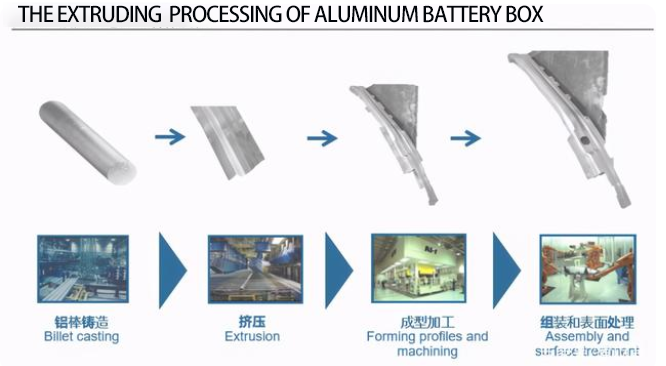

2. Kpọmkwem, usoro nke aluminum extrusion na-etolite batrị igbe bụ dị ka ndị a:

The ala efere nke igbe ahụ na-guzobere site esemokwu ịkpali ịgbado ọkụ mgbe aluminum mmanya extruded, na ala igbe ahu na-guzobere site ịgbado ọkụ na anọ n'akụkụ efere. Ugbu a, ndị mainstream aluminum profaịlụ na-eji nkịtị 6063 ma ọ bụ 6016, na tensile ike bụ ihu ọma n'etiti 220 ~ 240MPa, ma ọ bụrụ na ojiji nke elu ike extruded aluminum, tensile ike nwere ike iru ihe karịrị 400MPa, tụnyere nkịtị aluminum profaịlụ igbe nwere ike ibelata ibu site 20% ~ 30%.

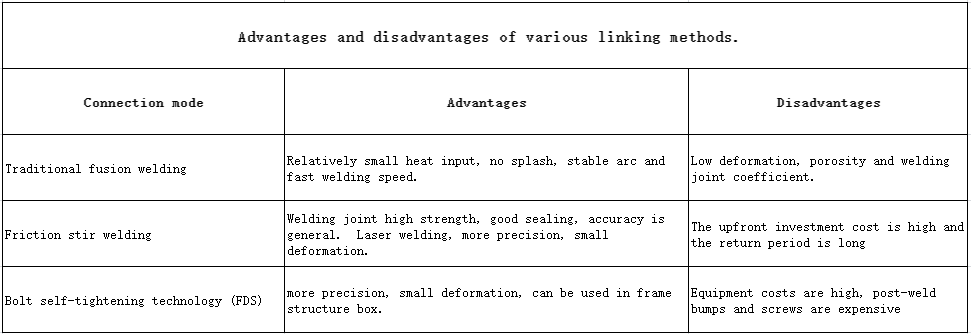

N'ihi mkpa ọ dị ịgbanye profaịlụ, teknụzụ ịgbado ọkụ nwere mmetụta dị ukwuu na ịdị larịị na izi ezi nke igbe batrị. A na-ekewa teknụzụ ịgbado ọkụ nke igbe batrị n'ime ịgbado ọkụ ọdịnala (TIG welding, CMT), ma ugbu a bụ ịgbado ọkụ nke mbụ (FSW), ịgbado ọkụ laser dị elu, teknụzụ na-ejide onwe ya (FDS) na teknụzụ njikọ.

TIG ịgbado ọkụ dị n'okpuru nchebe nke inert gas, na-eji arc eme n'etiti tungsten electrode na weldment ka ikpo gbazee isi metal na jupụta waya, nke mere na-etolite elu àgwà welds. Otú ọ dị, na evolushọn nke igbe Ọdịdị, igbe size na-aghọ ibu, profaịlụ Ọdịdị na-adị gịrịgịrị, na akụkụ ziri ezi mgbe ịgbado ọkụ na-mma, TIG ịgbado ọkụ bụ na mwepu.

CMT bụ usoro ịgbado ọkụ nke MIG / MAG ọhụrụ, na-eji nnukwu ihe mgbado ọkụ na-eme ka waya ịgbado ọkụ were were, site na esemokwu elu ihe, ike ndọda na nfuli igwe, na-akpụ weld na-aga n'ihu, yana obere ntinye ọkụ, enweghị splash, nkwụsi ike arc na ịgbado ọkụ ngwa ngwa na uru ndị ọzọ, enwere ike iji maka ịgbado ọkụ dị iche iche. Dịka ọmụmaatụ, igbe igbe dị n'okpuru ngwugwu batrị nke BYD na ụdị BAIC na-ejikarị teknụzụ ịgbado ọkụ CMT.

4. Ịgbado ọkụ ọdịnala nwere nsogbu dị ka nrụrụ, porosity na ọnụ ala ịgbado ọkụ na-akpata site na nnukwu ntinye ọkụ. Ya mere, ndị ọzọ ịrụ ọrụ nke ọma na green esemokwu ịkpali ịgbado ọkụ technology na elu ịgbado ọkụ àgwà e ọtụtụ-eji.

FSW dabeere na okpomọkụ eme site esemokwu n'etiti na-atụgharị ngwakọta agịga na aro ubu na isi metal dị ka okpomọkụ isi iyi, site na ntụgharị nke mixing agịga na axial ike nke aro ubu iji nweta plasticization eruba nke isi metal iji nweta ịgbado ọkụ nkwonkwo. FSW ịgbado ọkụ nkwonkwo na elu ike na ezi akara arụmọrụ na-ọtụtụ ebe na ubi nke batrị ịgbado ọkụ. Dịka ọmụmaatụ, igbe batrị nke ọtụtụ ụdị nke Geely na Xiaopeng na-anakwere usoro ịgbado ọkụ nwere akụkụ abụọ.

Ịgbado ọkụ nke laser na-eji eriri laser nwere ike dị elu iji mee ka elu nke ihe a na-agbanye ọkụ na-agbaze ihe ahụ ma mepụta nkwonkwo a pụrụ ịdabere na ya. Ejibeghị akụrụngwa ịgbado ọkụ laser eme ihe n'ọtụtụ ebe n'ihi nnukwu ọnụ ahịa nke itinye ego mbụ, ogologo oge nloghachi, yana ihe isi ike nke ịgbado ọkụ aluminom alloy laser.

5. Iji belata mmetụta nke ịgbado ọkụ deformation na igbe size ziri ezi, bolt self-tightening technology (FDS) na bonding technology na-ewebata, n'ime nke a ma ama ụlọ ọrụ bụ WEBER na Germany na 3M na United States.

Teknụzụ njikọ FDS bụ ụdị oyi na-akpụ usoro nke ịghasa onwe ya na njikọ bolt site na ịgbatị ogwe nke etiti akụrụngwa iji duzie ntụgharị ọsọ ọsọ nke moto a ga-ejikọ ya na okpomoku nke efere efere na nrụrụ plastik. A na-ejikarị rọbọt eme ihe ma nwee ogo akpaaka dị elu.

Na ubi nke ọhụrụ ume batrị mkpọ n'ichepụta, usoro na-tumadi etinyere na etiti Ọdịdị igbe, na bonding usoro, iji hụ na zuru ezu njikọ ike mgbe aghọta akara arụmọrụ nke igbe. Dịka ọmụmaatụ, igbe batrị nke ụdị ụgbọ ala nke NIO na-eji teknụzụ FDS wee mepụta ya nke ọma. Ọ bụ ezie na teknụzụ FDS nwere uru doro anya, ọ nwekwara ọghọm: ọnụ ahịa akụrụngwa dị elu, ọnụ ahịa dị elu nke protrusion na skru post-weld, wdg, na ọnọdụ ọrụ na-egbochikwa ngwa ya.

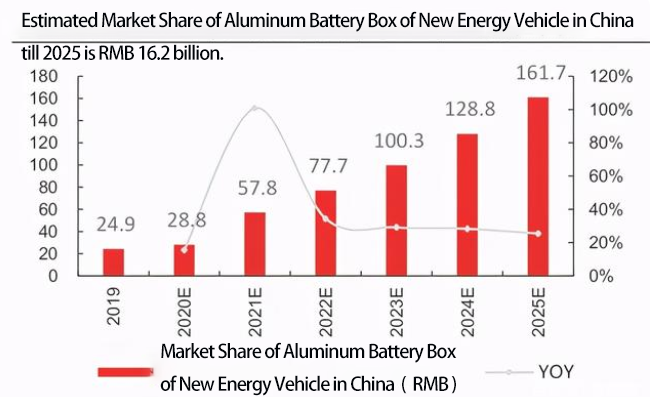

Part 3. Market Share: batrị igbe ahịa ohere bụ nnukwu, na ngwa ngwa compound ibu

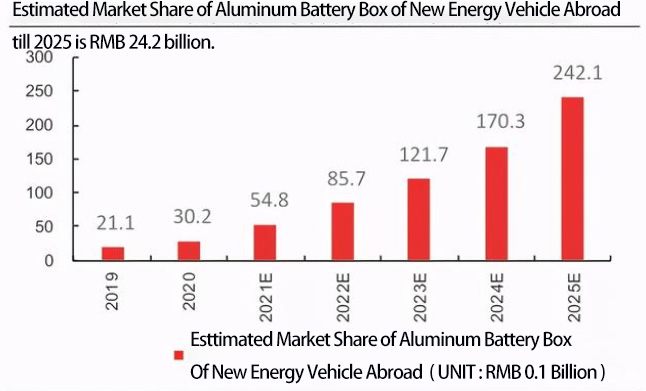

Ụgbọ ala eletrik dị ọcha na-aga n'ihu na-abawanye na olu, na ohere ahịa nke igbe batrị maka ụgbọ ala ike ọhụrụ na-agbasa ngwa ngwa. Dabere na atụmatụ ịzụ ahịa ụlọ na nke ụwa nke ụgbọ ala ume ọhụrụ, anyị na-agbakọ oghere ahịa ụlọ nke igbe batrị ike ọhụrụ site na icheta nkezi uru otu nkeji nke igbe batrị ike ọhụrụ:

Echiche ndị bụ isi:

1) Olu ire nke ụgbọ ala ume ọhụrụ na China na 2020 bụ nde 1.25. Dị ka atụmatụ mmepe nke Ọkara na ogologo oge nke ụlọ ọrụ ụgbọ ala nyere site na ministri na kọmitii atọ, ọ bụ ihe ezi uche dị na ya iche na olu ire ụgbọ ala ndị njem ume ọhụrụ na China na 2025 ga-eru nde 6.34, na mmepụta nke ụgbọ ala ume ọhụrụ na mba ofesi ga-eru nde 8.07.

2) Olu ire ụlọ nke ụgbọ ala eletrik dị ọcha ruru 77% na 2020, na-eche na olu ahịa ahụ ga-aza 85% na 2025.

3) The permeability nke aluminum alloy igbe batrị na bracket na-edobe na 100%, na uru nke otu igwe kwụ otu ebe bụ RMB3000.

Nsonaazụ ngụkọ: a na-eme atụmatụ na ka ọ na-erule 2025, oghere ahịa nke igbe batrị maka ụgbọ ala ndị njem ume ọhụrụ na China na esenidụt ga-abụ ihe dịka ijeri RMB 16.2 na ijeri RMB 24.2, na ọnụego uto sitere na 2020 ruo 2025 ga-abụ 41.2% na 51.7%

Oge nzipu: Mee-16-2022