Gịnị bụ aluminom extrusion?

N'ime afọ ndị na-adịbeghị anya, aluminom extrusion na-ejikarị emewe ụlọ ọrụ mmepụta ihe na mmepụta ihe.Ị nwere ike ịnụ maka usoro nrụpụta a mana emela ya'maghị ka o si arụ ọrụ.Taa, anyị ga-eme ka ị nwee nghọta doro anya banyere ya n'agbanyeghị edemede a.

1. Gịnị bụ Aluminom Extrusion?

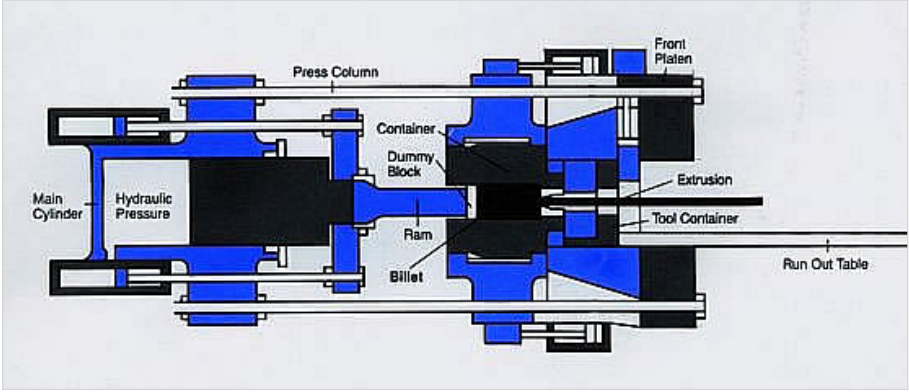

Aluminom extrusion bụ usoro nke aluminom alloy ihe na-amanye site a anwụ na a kpọmkwem cross-section profaịlụ.Enwere ike iji ya tụnyere ịpịnye ntacha eze site na tube.Ebulu dị ike na-ebugharị aluminom site na anwụ anwụ wee pụta site na oghere anwụ.Mgbe ọ na-eme ya, ọ na-apụta n'ụdị nke anwụ anwụ wee dọpụta ya na tebụl gbapụrụ agbapụ.

2. Ebee ka aluminom extrusion nwere ike tinye?

Enwere ike iji extrusion aluminom mee ihe n'ọtụtụ akwụkwọ, dị ka windo na ọnụ ụzọ n'ichepụta, mgbidi ákwà mgbochi imewe na mmepụta ihe, ụgbọala, ike ndụ ndụ, ngwaọrụ nkwurịta okwu, ngwa ụlọ, akụrụngwa na ihe ndị ọzọ.

Rui Qifengnwere ike ịnye ngwaahịa extrusion dị iche iche nke aluminom iji mee ihe dị iche iche nke profaịlụ aluminom.Anyị na CALCO na-arụkọ ọrụ ozugbo, aka mbụ nke akụrụngwa aluminom, ga-enye gị ogo dị elu yana ọnụ ahịa dị mma.

Biko kpọtụrụ anyị ozugbo ma ọ bụrụ na ị nwere aluminom extrusion chọrọ.

3. Gịnị bụ aluminom extrusion usoro?

Nzọụkwụ 1: Extrusion anwụ ịbịaru imewe ma mee ka extrusion nwụọ.

Kwụpụ 2: Na-ekpo ọkụ extrusion na-anwụ n'etiti 450-500 degrees Celsius ma tinye ya na extrusion pịa.

Kwụpụ 3: Na-ekpocha mkpanaka aluminom ka ọ dị n'etiti 400-500 Celsius ma nyefee ya na mpempe akwụkwọ extrusion.A na-etinye mmanụ mmanu (ma ọ bụ ihe ntọhapụ) na mkpanaka aluminom na ebule extrusion, iji gbochie mkpanaka aluminum na ebule ịrapara ọnụ.

Kwụpụ 4: Na-agbanye mkpanaka aluminom n'ime akpa ahụ wee pụta ihe aluminom si na oghere anwụ na-apụta n'ụdị profaịlụ zuru oke.

Kwụpụ 5: A na-eduzi extrusions n'akụkụ tebụl gbapụrụ agbapụ wee menyụọ, ma ọ bụ mee ka mmiri saa mmiri ma ọ bụ ndị fan na-eme ka ọ dị mma n'elu tebụl.

Nzọụkwụ 6: Extrusions ga-akpụ a na-ekpo ọkụ saws na tebụl-ogologo ikewapụ ya na extrusion usoro.

Kwụpụ 7: Na-eme ka extrusion ahụ dị jụụ n'ime ụlọ ma bugharịa ha na akwa akwa ma gbatịa n'ime nhazi.Mgbatị bụ imezi mgbagọ eke mere na profaịlụ.

Kwụpụ 8: Beechapụ extrusion ahụ n'ogologo kwesịrị ekwesị wee bịa na nhazi omimi nke CNC.

Nzọụkwụ 9: ịka nká na T5 ma ọ bụ T6 iwe.

Nzọụkwụ 10: Ọgwụgwọ okpomọkụ na ọgwụgwọ elu.Ọgwụgwọ okpomọkụ nwere ike imeziwanye ihe eji arụ ọrụ.Ọgwụgwọ n'elu nwere ike ịkwalite ọdịdị dị ka nchebe corrosion.Ngwọta dị n'elu gụnyere mkpuchi ntụ ntụ, anodized, ọka osisi, brushed, sandblasting, electrophoresis, polishing na PVDF mkpuchi na na.Anyị ga-ewebata gị na ọgwụgwọ elu na edemede dị iche iche.

Rui Qifengbụ ọkachamara na-ere ahịa nke nwere ike ịnye ngwọta profaịlụ aluminom otu nkwụsị.N'agbanyeghị ihe achọrọ na profaịlụ aluminom, enwere nhọrọ dịgasị iche iche maka gị iji gboo mkpa gị akọwapụtara na ọrụ.Nabata n'ihujụrụọ bụrụ na ị nwere mmasị.

https://www.aluminum-artist.com/

Jenny.xiao@aluminum-artist.com

Oge nzipu: Feb-08-2023